Mechanically Jointed Beams

HNV+

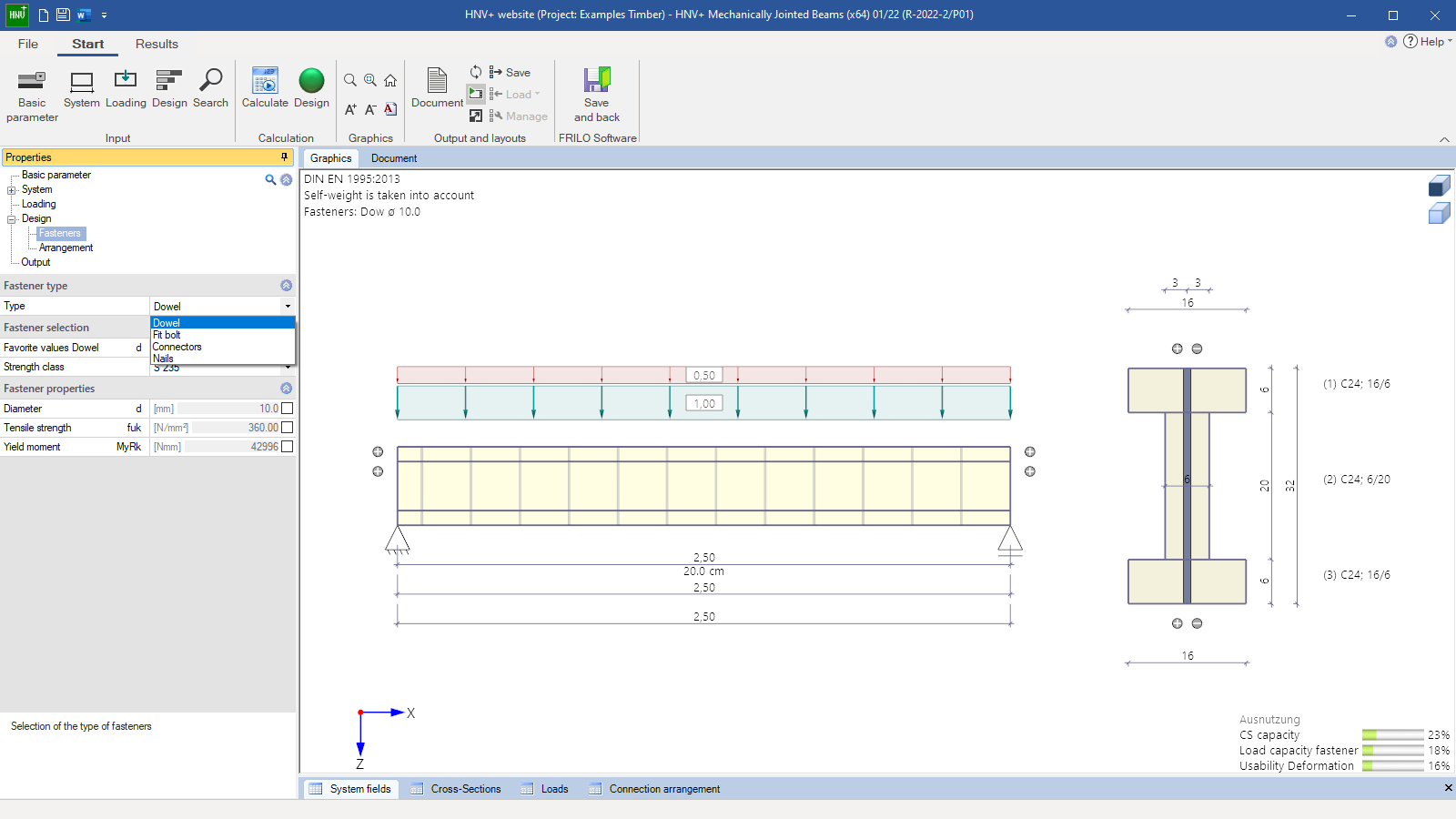

The program HNV+ is used to design mechanically connected wooden beams. Different timber cross-sections can be stacked and connected by means of fasteners. The various elements can be of different timber materials and the fasteners can have different spacing.

Discover now more programs from the section Timber & Roof!

SHOW MOREMaterial

- Softwood of the strength classes C14 to C50

- Hardwood of the strength classes D18 to D80

- Glulam of the strength classes GL20c/h to GL32c/h

- User-defined material

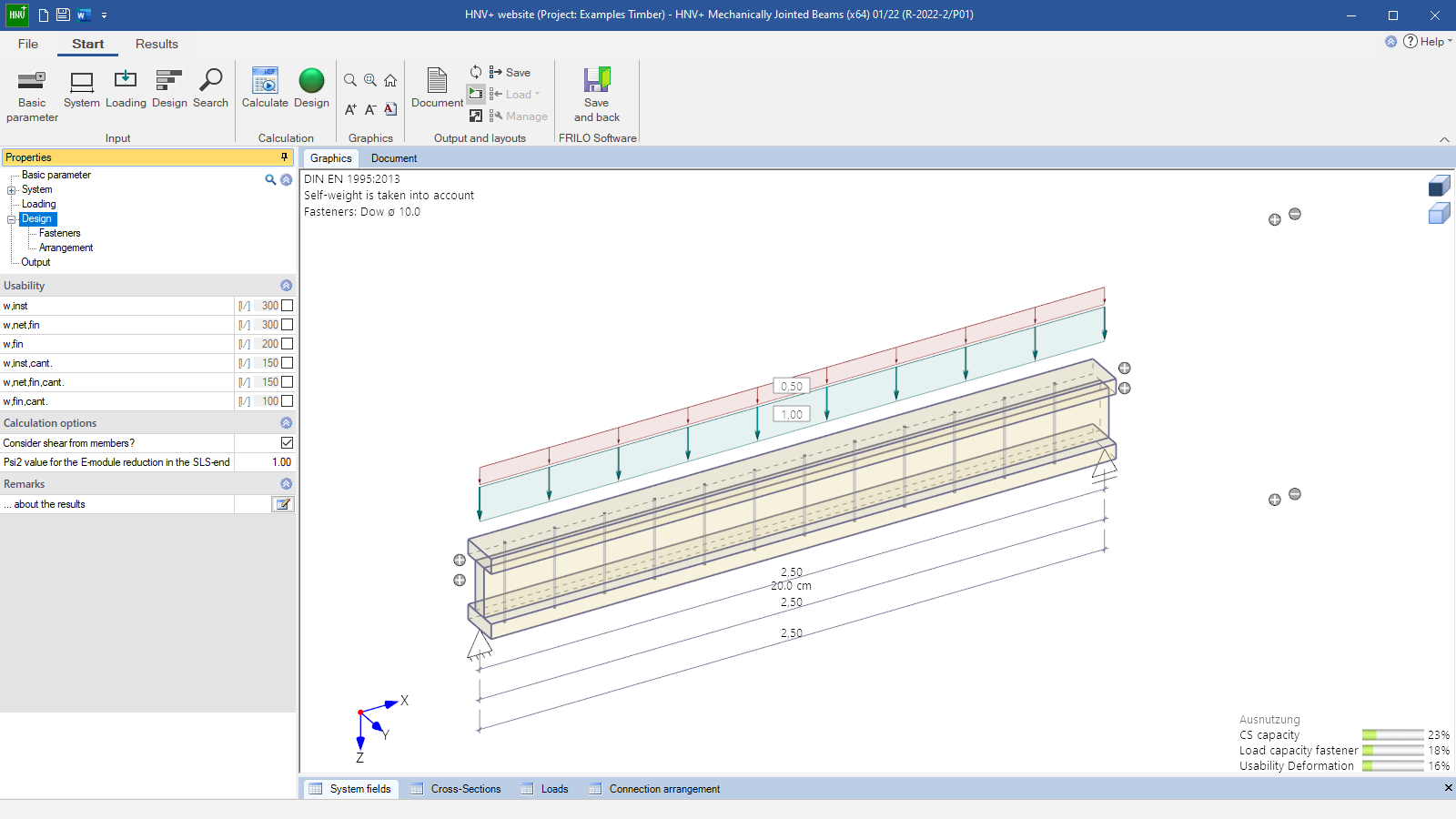

Structural system

- Single-span beam

- Multi-span beam

- Cantilevers

Loads

Vertical load:

- Uniformly distributed linear load

- Concentrated load

- Trapezoidal load

Cross-sections

Type 1:

- Rectangular cross-sections

- Any number of stacked cross-sections

Type 2:

- Cross-sections consisting of the upper and lower flange and the webs

- Different materials

Ultimate limit state

In the ultimate limit state, both the initial and the final state are calculated. This provides for compliance with the standard, which requires that when the distribution of internal forces is influenced by the stiffness distribution, the deformation coefficient affects the moduli of elasticity, shear, and displacement.

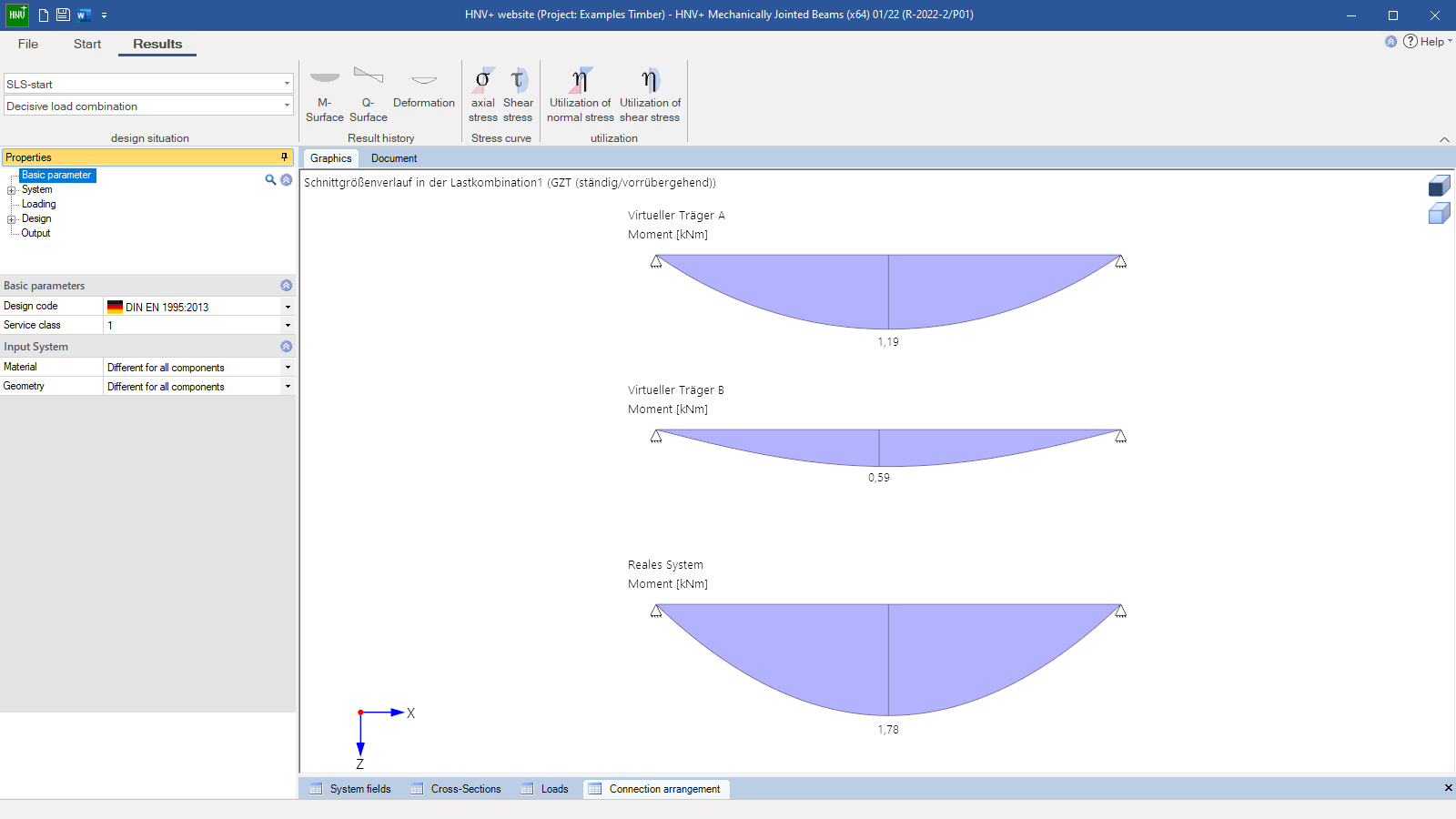

Method of shear analogy

The design is performed using the method of shear analogy. Two virtual beams are generated which are coupled in their deformation but have different stiffnesses. The stresses of the two beams are then used to perform the verifications.

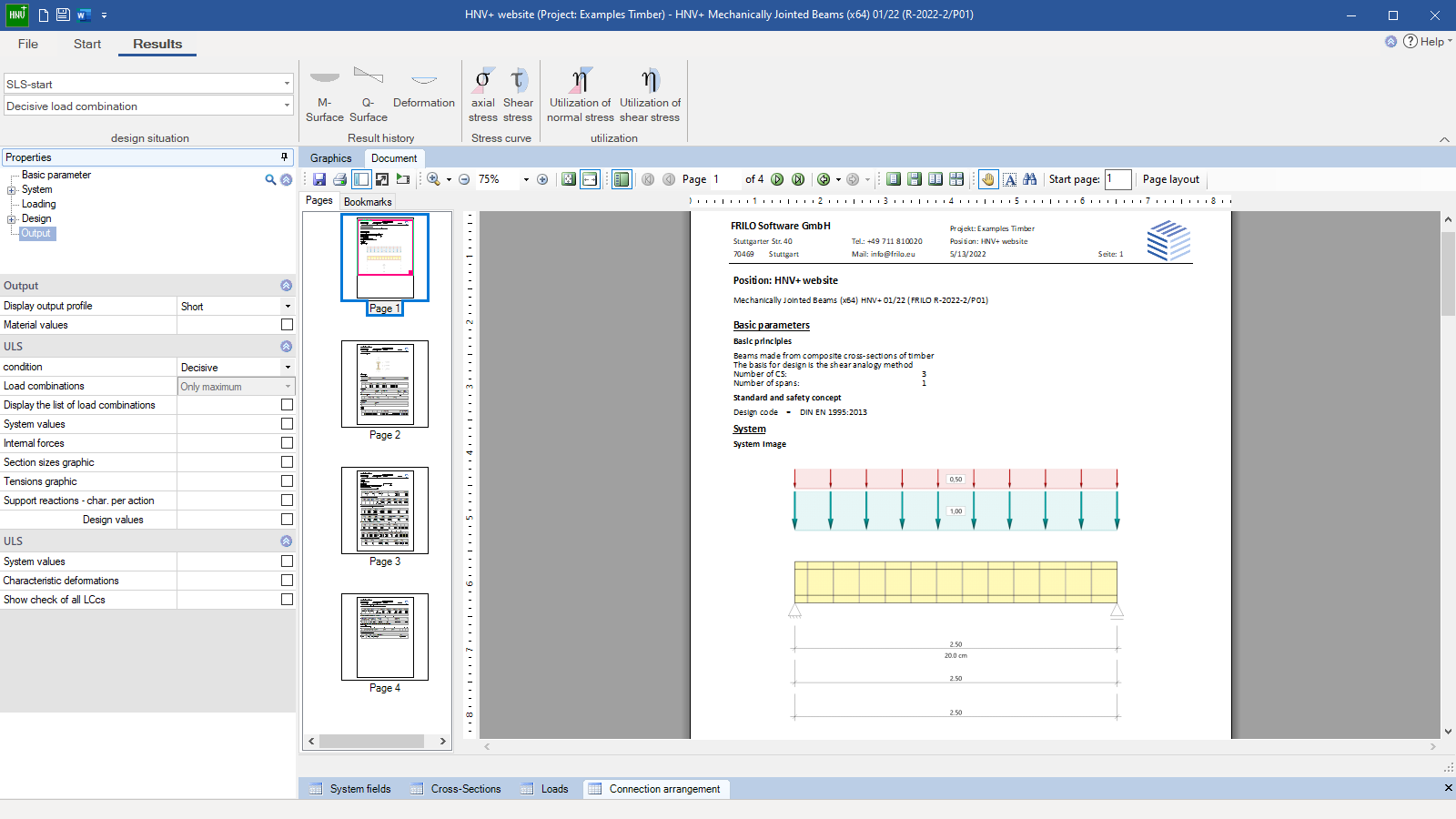

Document file formats

- Word

- Printer

Output

A user-defined scope is selectable.

Timber construction

- DIN 1052

- DIN EN 1995

- ÖNORM EN 1995

- NTC EN 1995

- BS EN 1995

- PN EN 1995

- EN 1995

News

Merger of FRILO Software and DC Software with ALLPLAN successfully completed

The merger of FRILO Software GmbH and DC-Software Doster & Christmann GmbH with the ALLPLAN Group has been legally completed since July 1, 2024.

Corporate headquarters as reinforced concrete skeleton structure

With the construction of a new corporate headquarters, Heidelberg Materials has demonstrated the remarkable range of reinforced concrete as an attractive building material. FRILO and Allplan were used by the structural engineers.