Timber Wall Diaphragms

HTW+

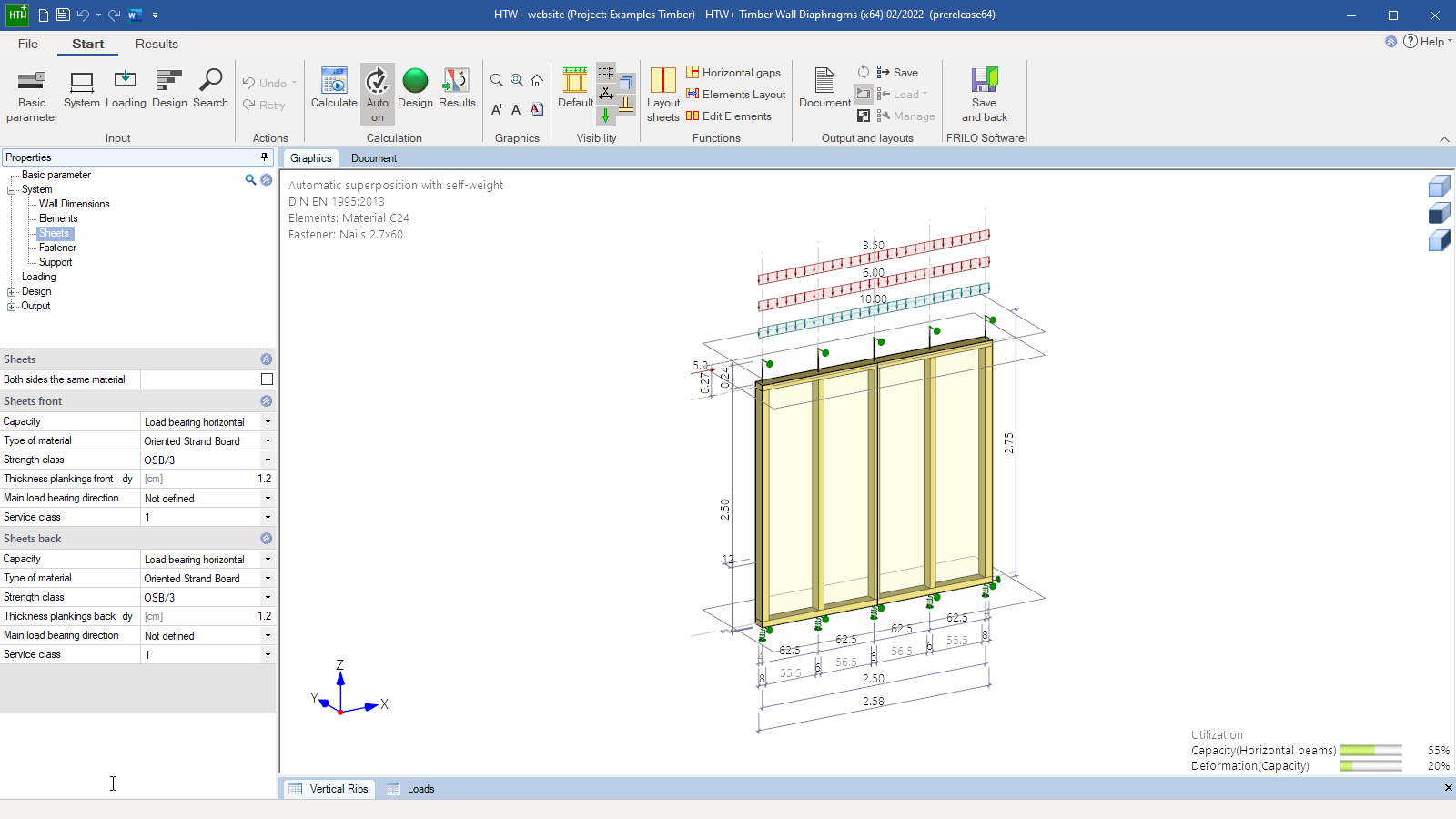

The HTW+ program is used to calculate wall panels (diaphragms) according to Eurocode 5 and its National Annexes. The variety of definable systems ranges from simple walls with regular rib spacing and identical panelling on both sides to irregular column placement with different panelling and different panel grids on each side. A horizontal butt joint can be defined for an individual, several or all panels. Different materials can be assigned to each rib and each panelled side.

Discover now more programs from the section Timber & Roof!

SHOW MOREMaterial

Rib materials

- Softwood of the strength classes C14 to C50

- Hardwood of the strength classes D18 to D80

- Glulam of the strength classes GL20c/h to GL32c/h

Panelling materials

- Plywood

- Oriented strand board

- Chipboard

- Fibreboard

- Gypsum board

Structural system

- Simple walls with regular and irregular rib spacing

- Identical or different panelling on either side

- Freely selectable position of each column

- Identical or different panel grid on either side

- Horizontal butt joint available for individual, several or all panels

- Identical or different materials and/or cross-sections on either panelled side and for each rib

- Vertically continuous edge ribs are available (without a base frame to bear transverse pressure)

Loads

- Vertical loads:

- concentrated

- uniformly distributed

- trapezoidal loads

- Horizontal concentrated load in the direction of the wall axis

- Area loads over the wall height in the transverse direction

- Accidental loads

- Seismic loads

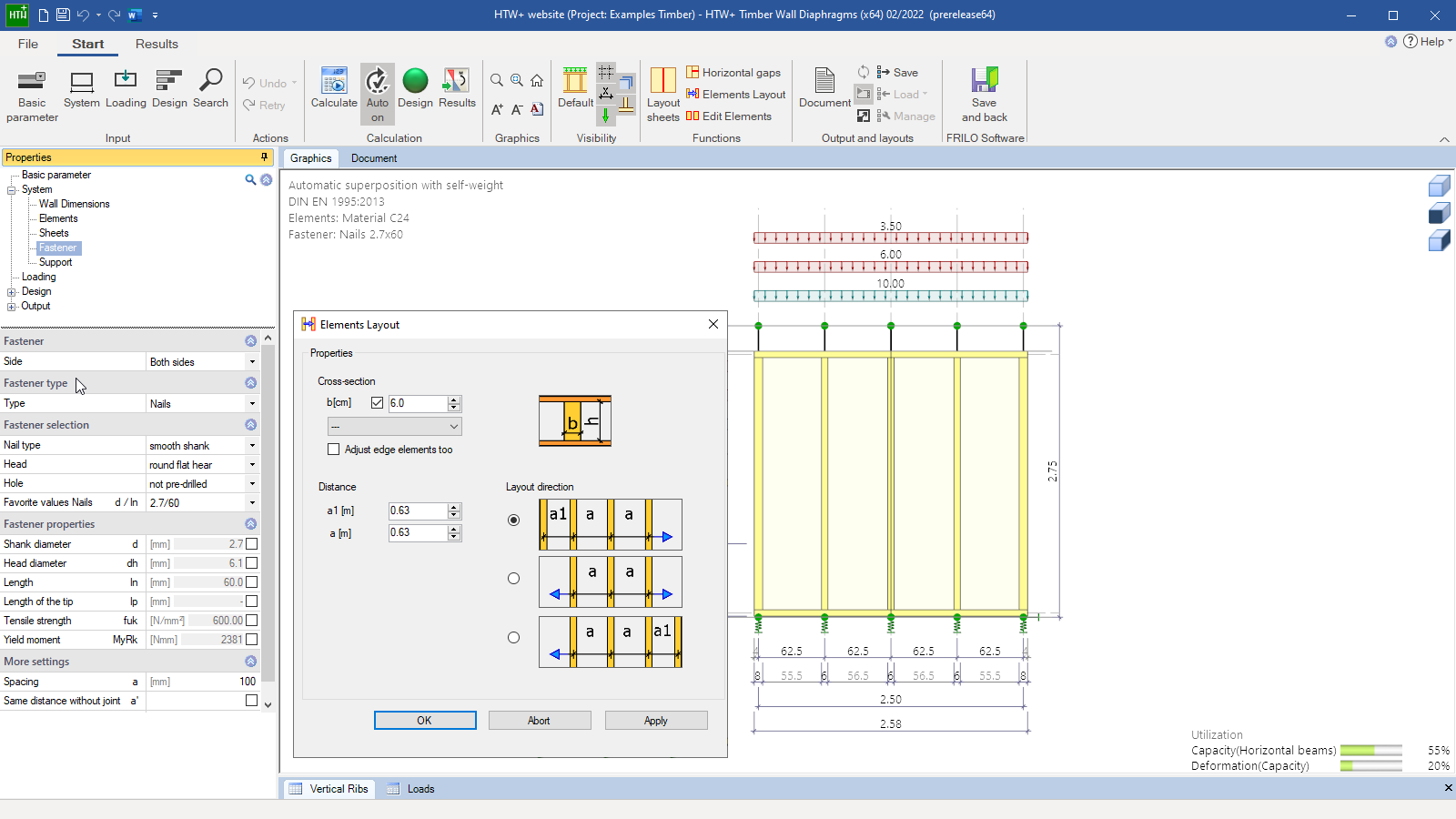

Fasteners

- Nails

- Bolts

- Brackets

- Glue

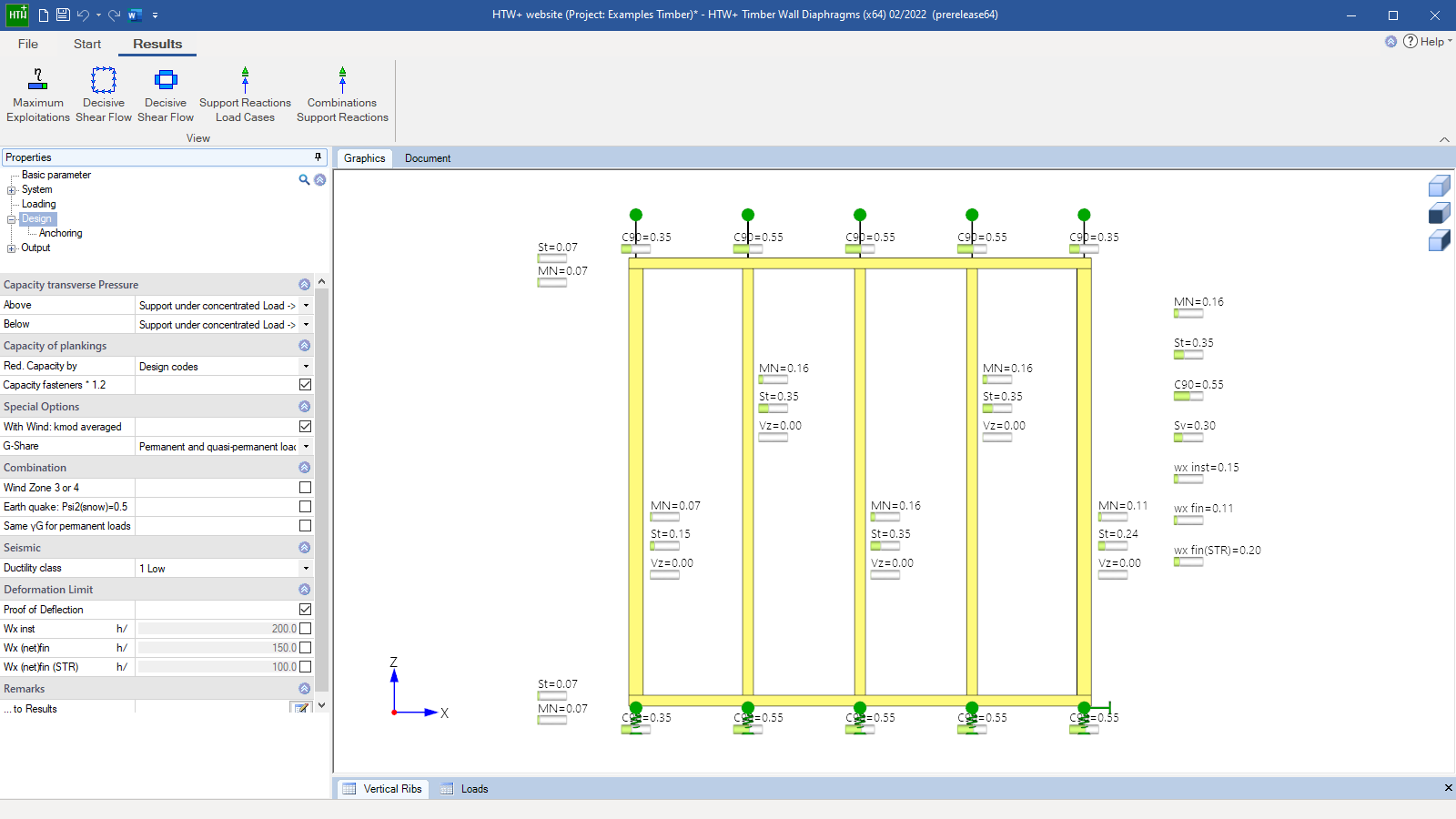

Design

The panelling is calculated as a shear panel (9.2.4.2 method A), which bears the horizontal loads in the direction of the wall axis. Vertical forces are borne by the vertical ribs.

In addition to the standard safety verifications, also the decisive anchoring forces for the position stability and the deformations are calculated in the serviceability verifications including creep.

The stiffnesses of the fasteners and the support, the bending stiffness and the shear stiffness are taken into account. The stiffness types including the required reductions are calculated for all components. Support stiffness (specified by the user) is handled with separate tension and compression springs on the edge ribs. The compression springs of the base frames can be calculated optionally.

The verifications of the stresses and the stability of the ribs are performed as per 6.3.2 and the transversal rib compression as per 6.1.5. The verification model (base frame pressure or bearing stress) is optionally selectable

The verifications of the panelling (shear) and the fasteners include the relevant increase factors and reduction factors (9.2.4.2).

The application of the increase factor can optionally be disabled. If panelling on both wall sides was defined, different stiffness on each side can be taken into account (optionally with consideration of the real stiffness). Serviceability verifications are performed based on the calculated stiffness.

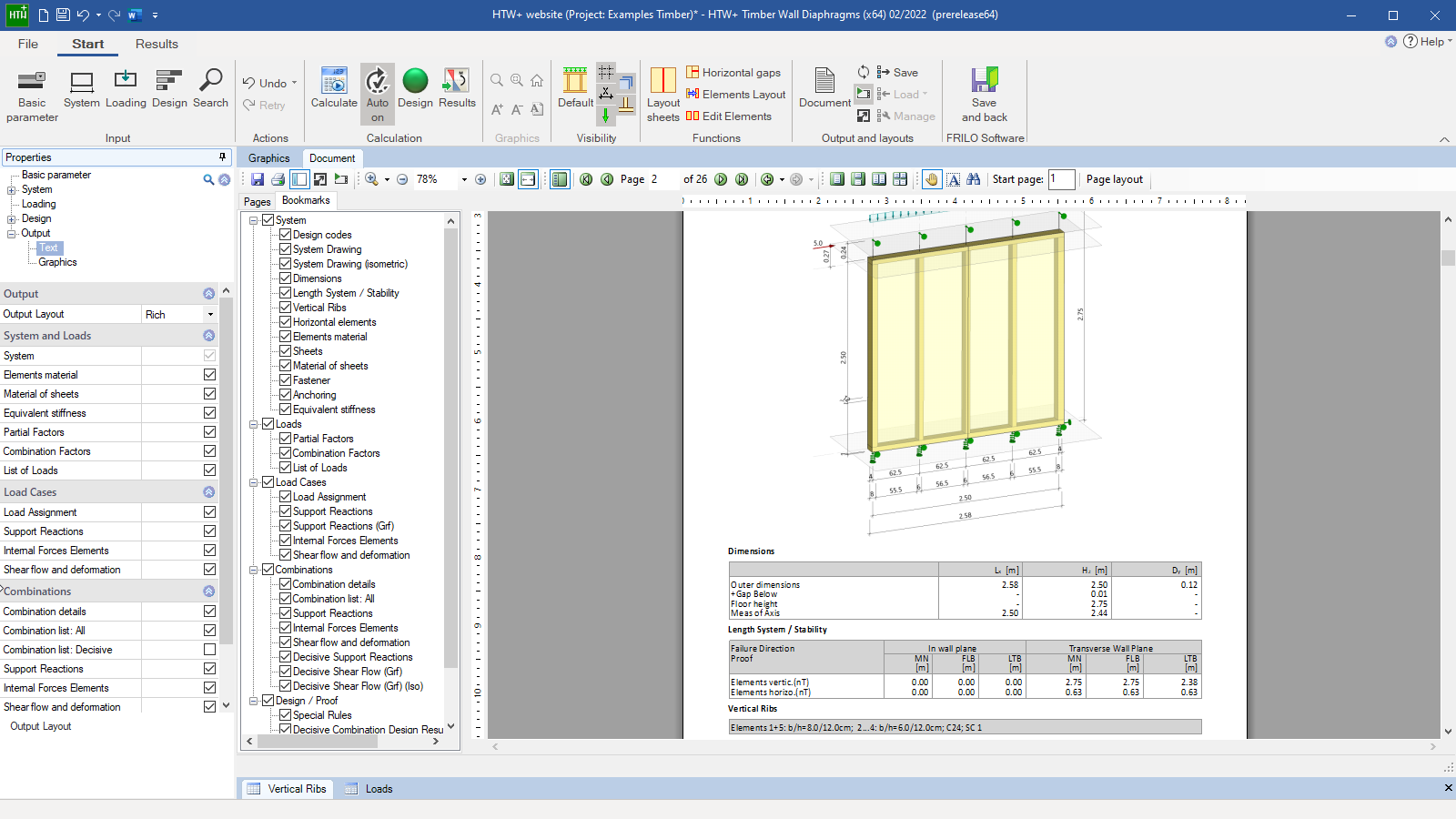

Document file formats

- Word

- Printer

Output

- User-defined scope

- Additional result graphs:

- Maximum utilization for all verifications

- Decisive shear flow in the front and rear panelling

Würth panel anchors

To anchor the end ribs, the program supports the design of two-piece Würth panel anchors.

Timber construction

- DIN EN 1995

- ÖNORM EN 1995

- NTC EN 1995

- BS EN 1995

- PN EN 1995

- EN 1995

- DIN 1052

Support resources

News

FRILO launches version 2024-2 with powerful updates for structural analysis and design

Highlights include the optimised design of Schöck Isokörbe®, the advanced integration of DC foundation engineering programs into the FRILO environment and new RSX interfaces for detail verifications in steel construction.

Load determination for eight-floor perimeter block development with FRILO Building Model

Find out how the structural engineers at bauart Konstruktions GmbH determined the loads for an eight-floor perimeter block development in Frankfurt’s Europaviertel district using the GEO from FRILO.