Steel Connection

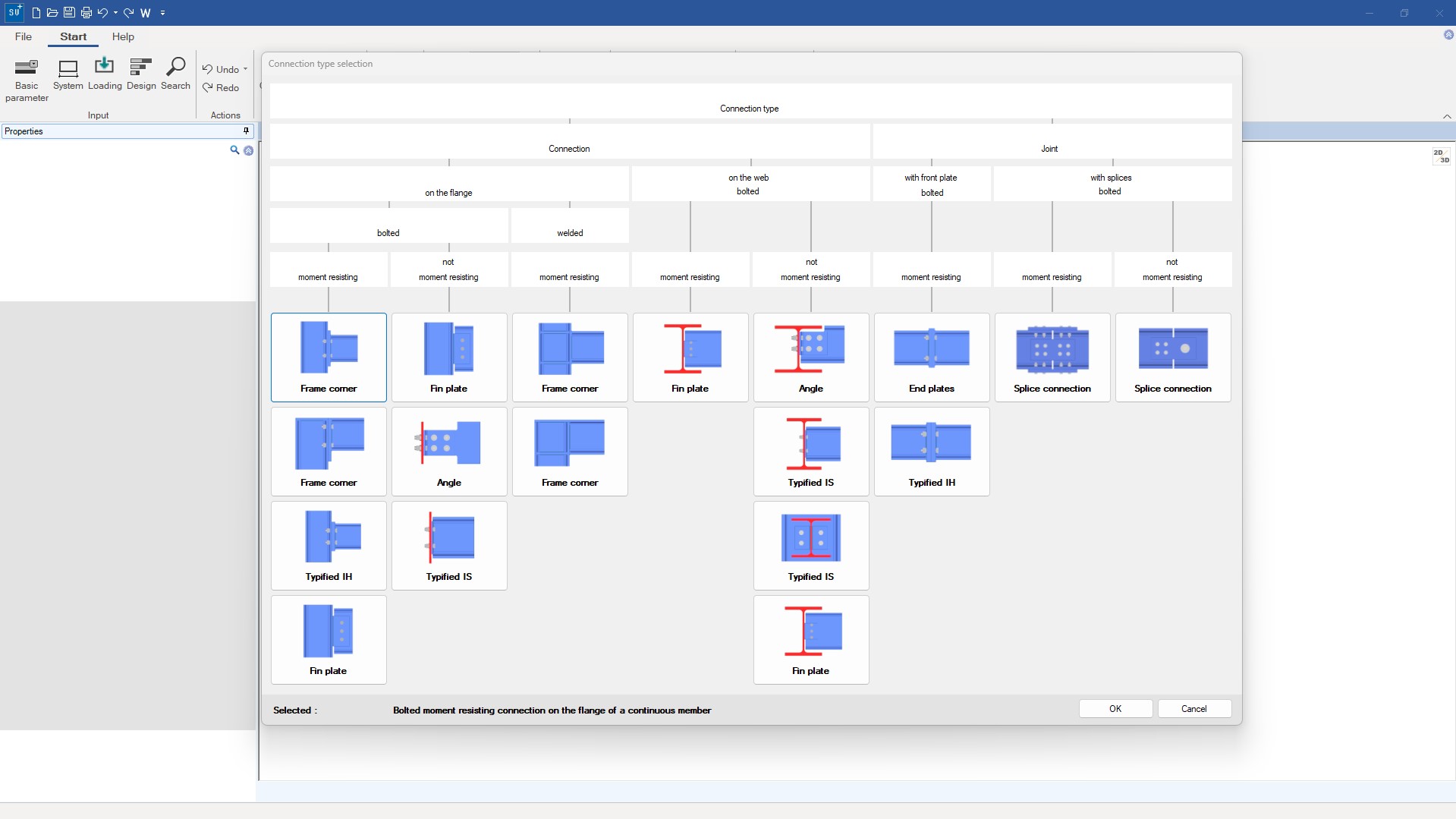

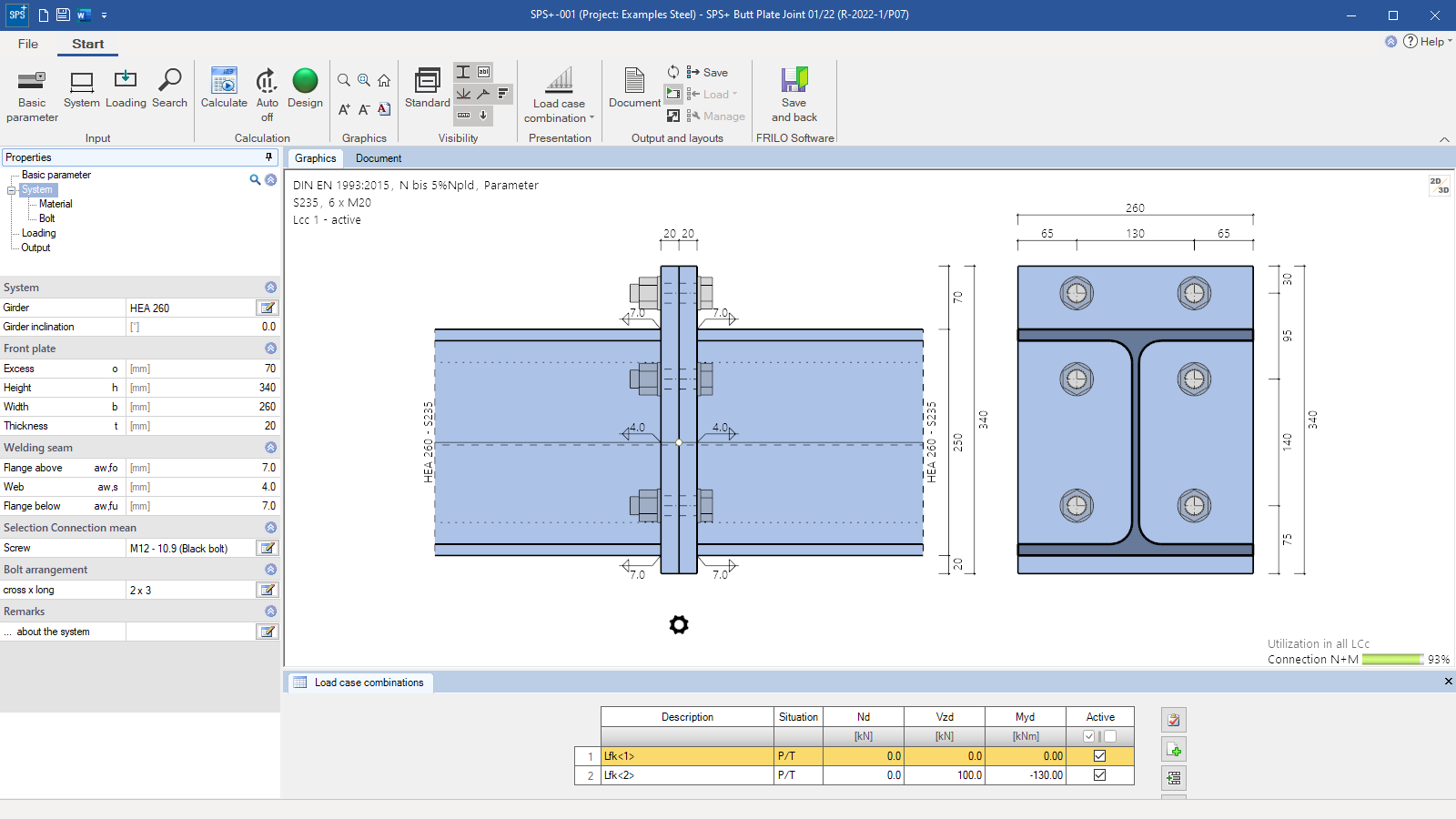

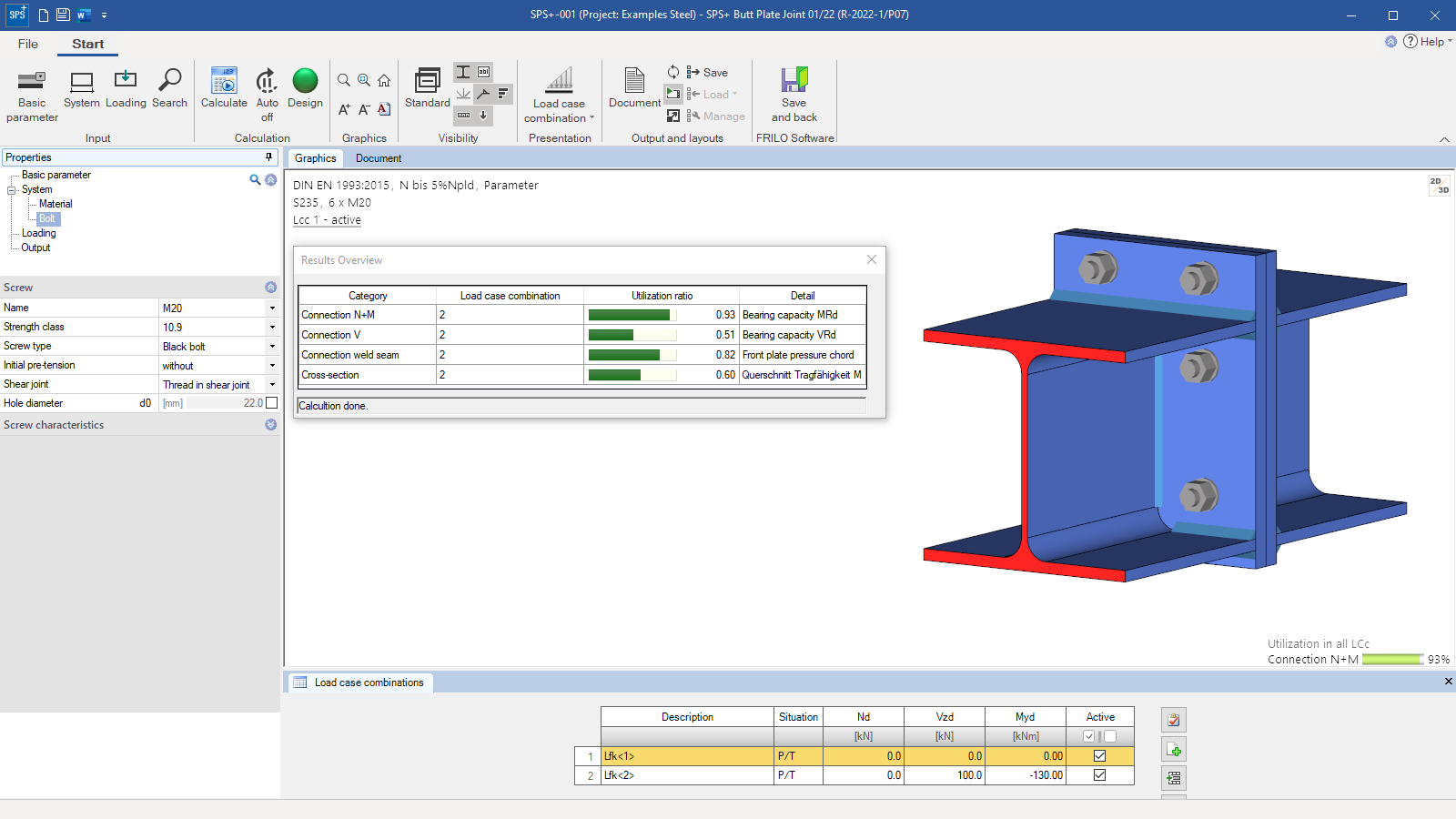

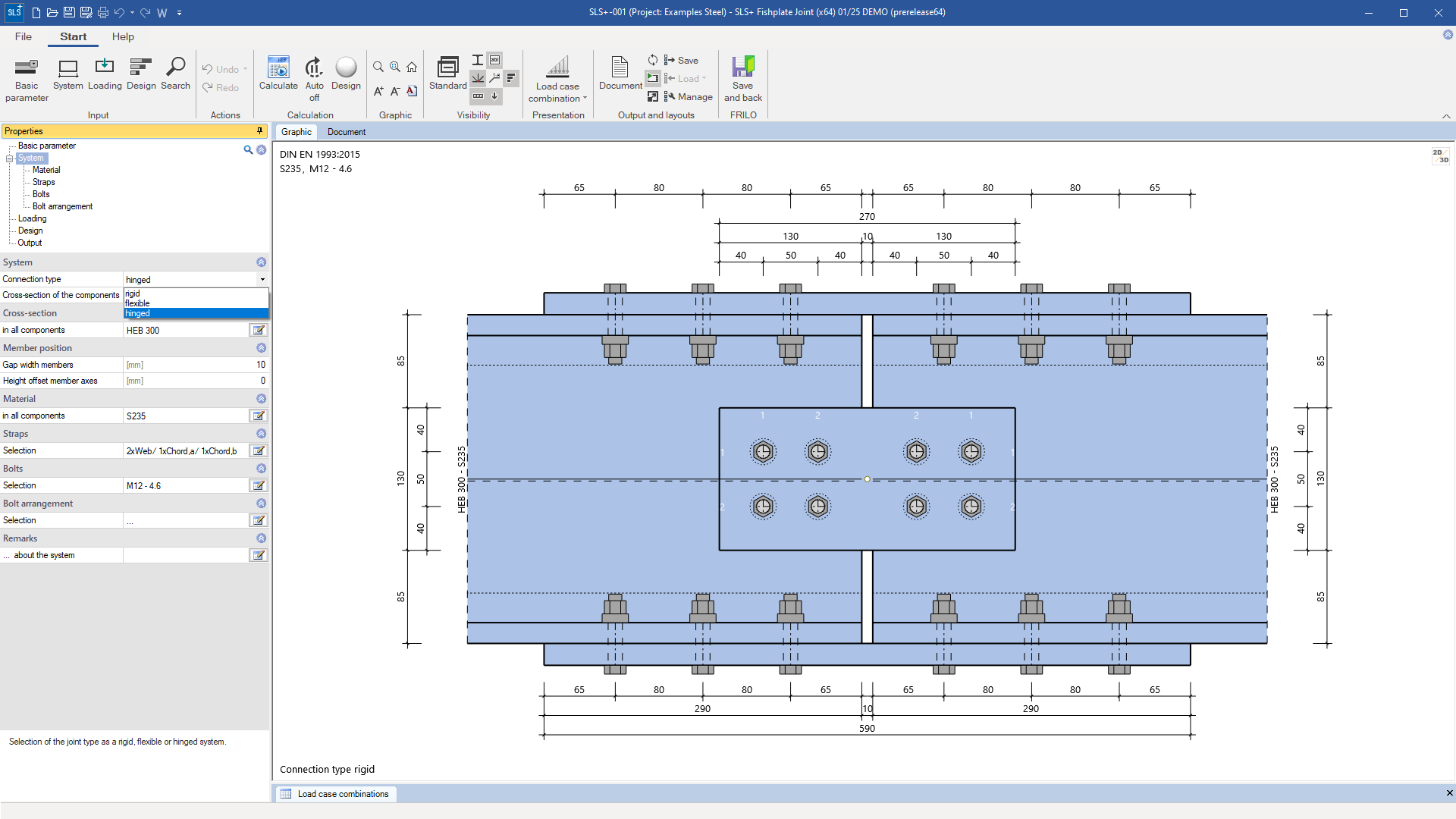

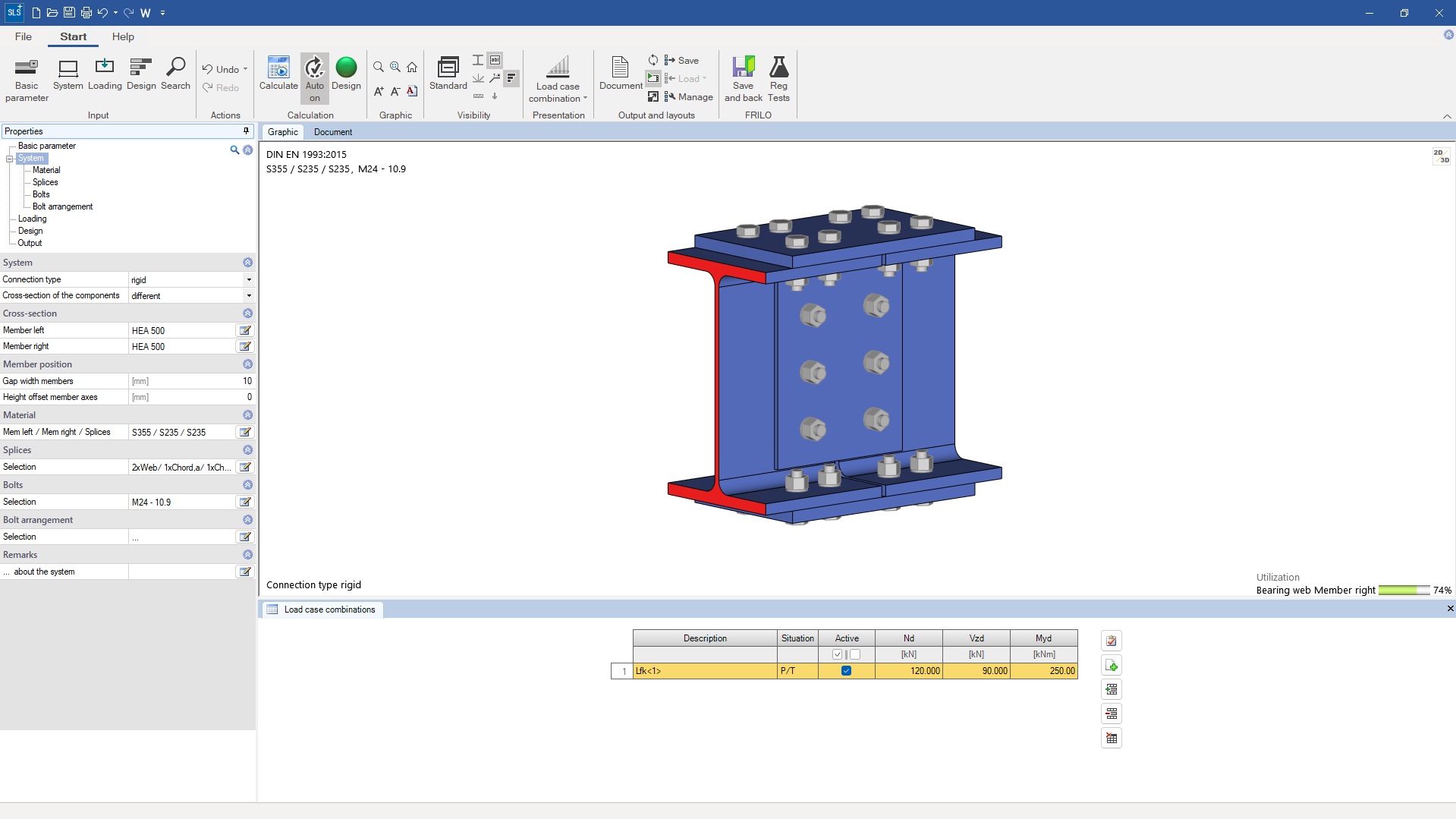

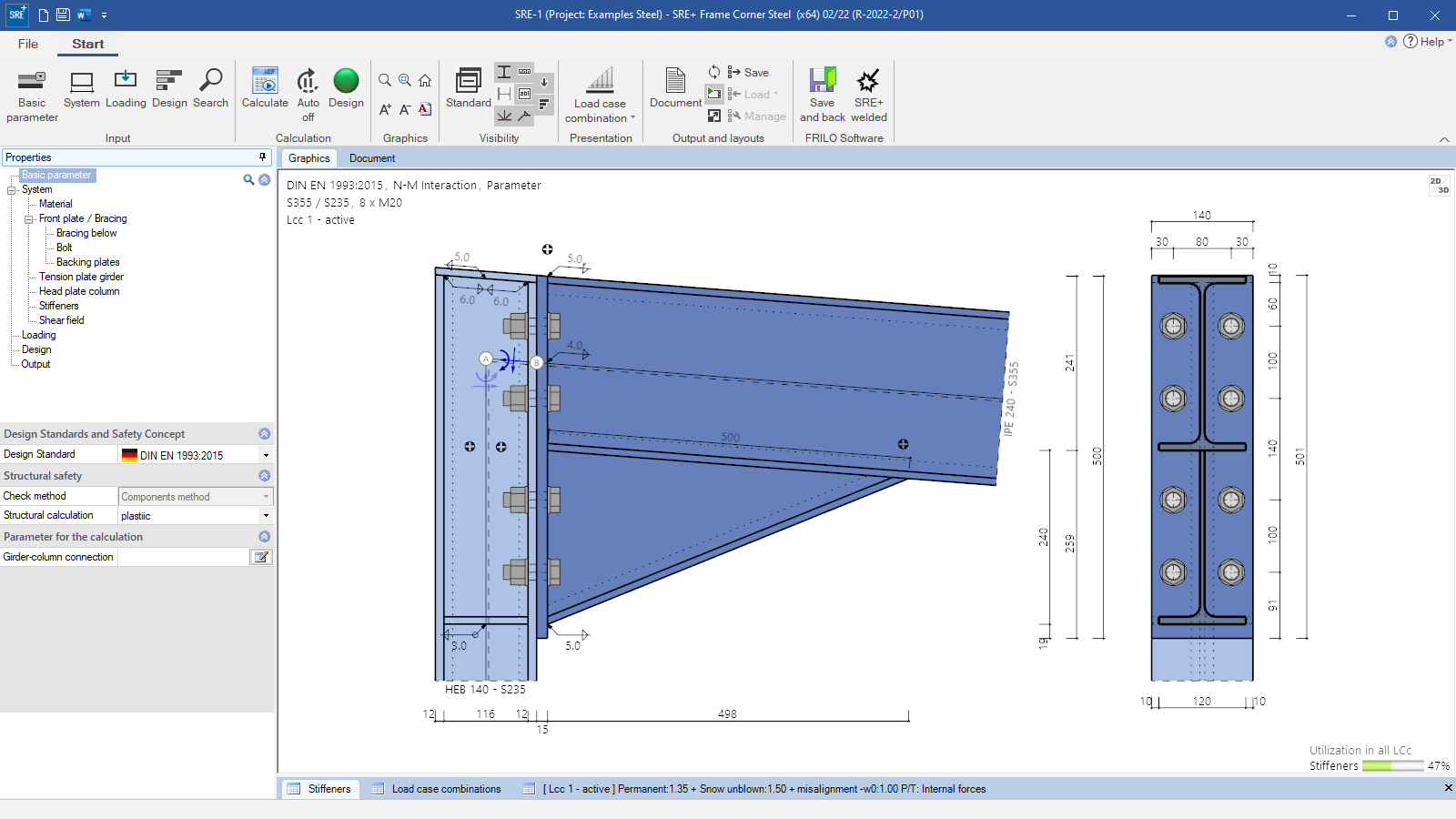

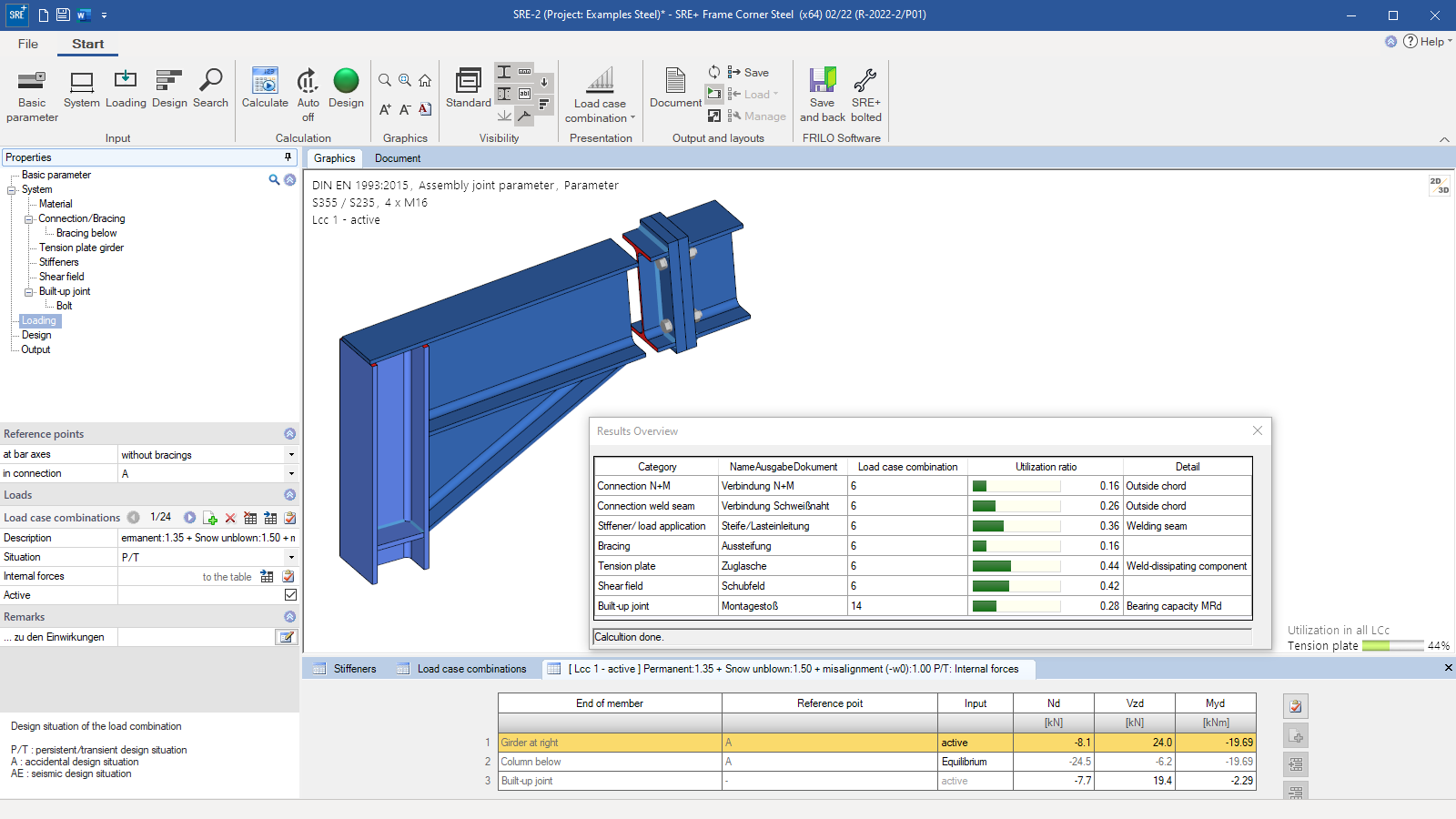

The “Steel Connection” program can be used to analyze and design steel connections such as butt plate joints, fin plates, welded and bolted frame corners, splice connections, steel angle connections, and typified steel connections.

Only available in FRILO Ultimate

Core capabilities

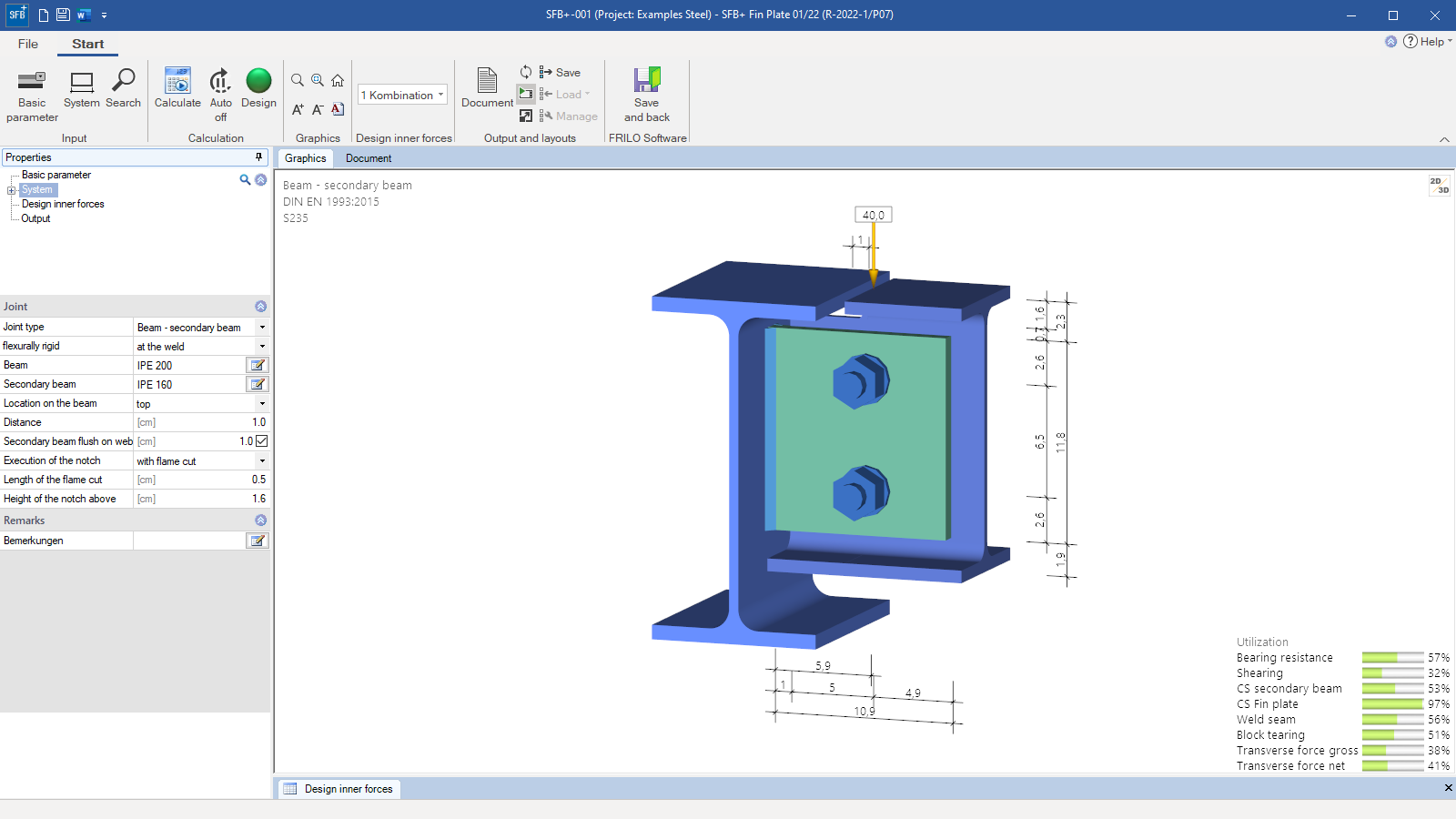

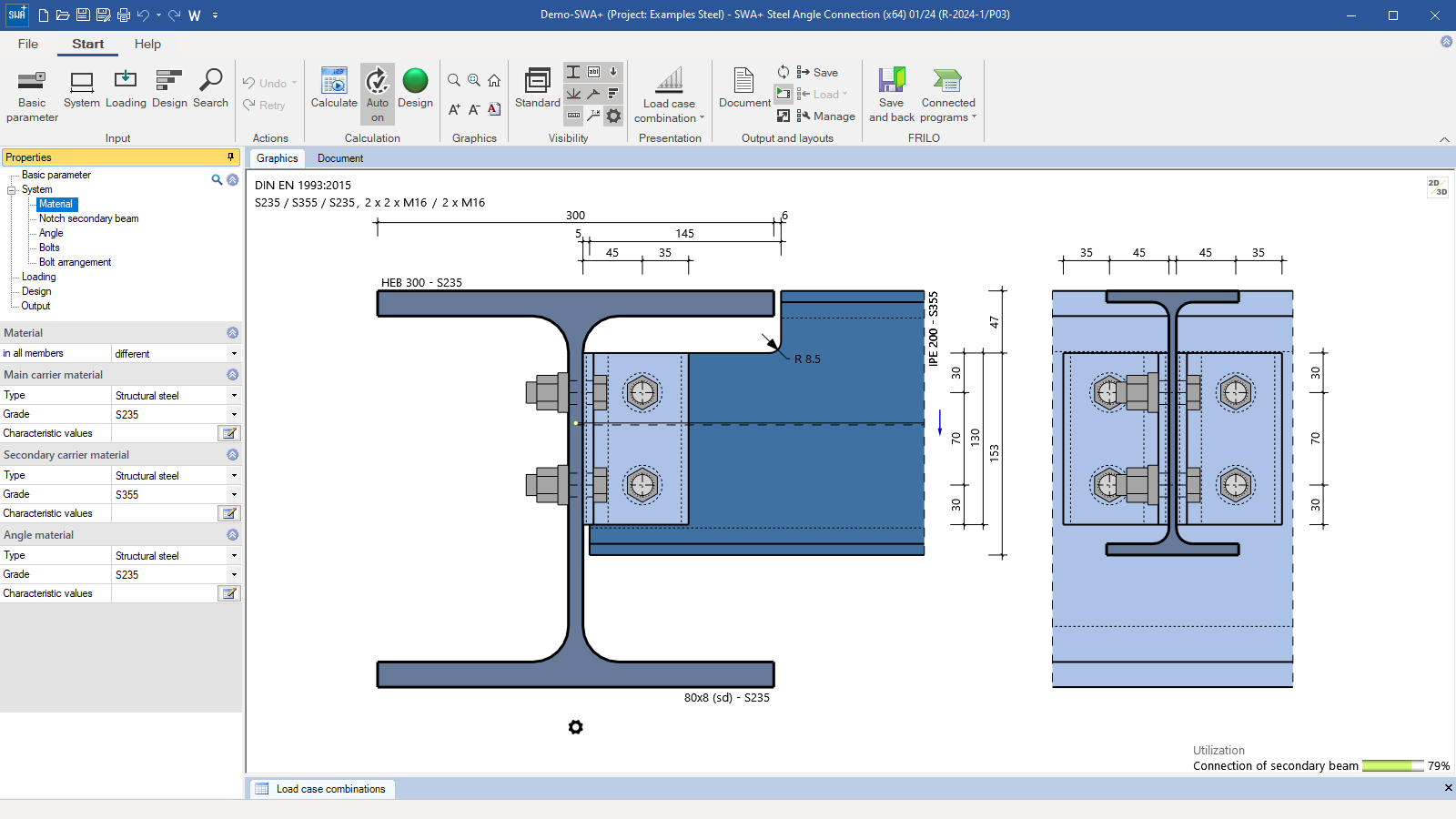

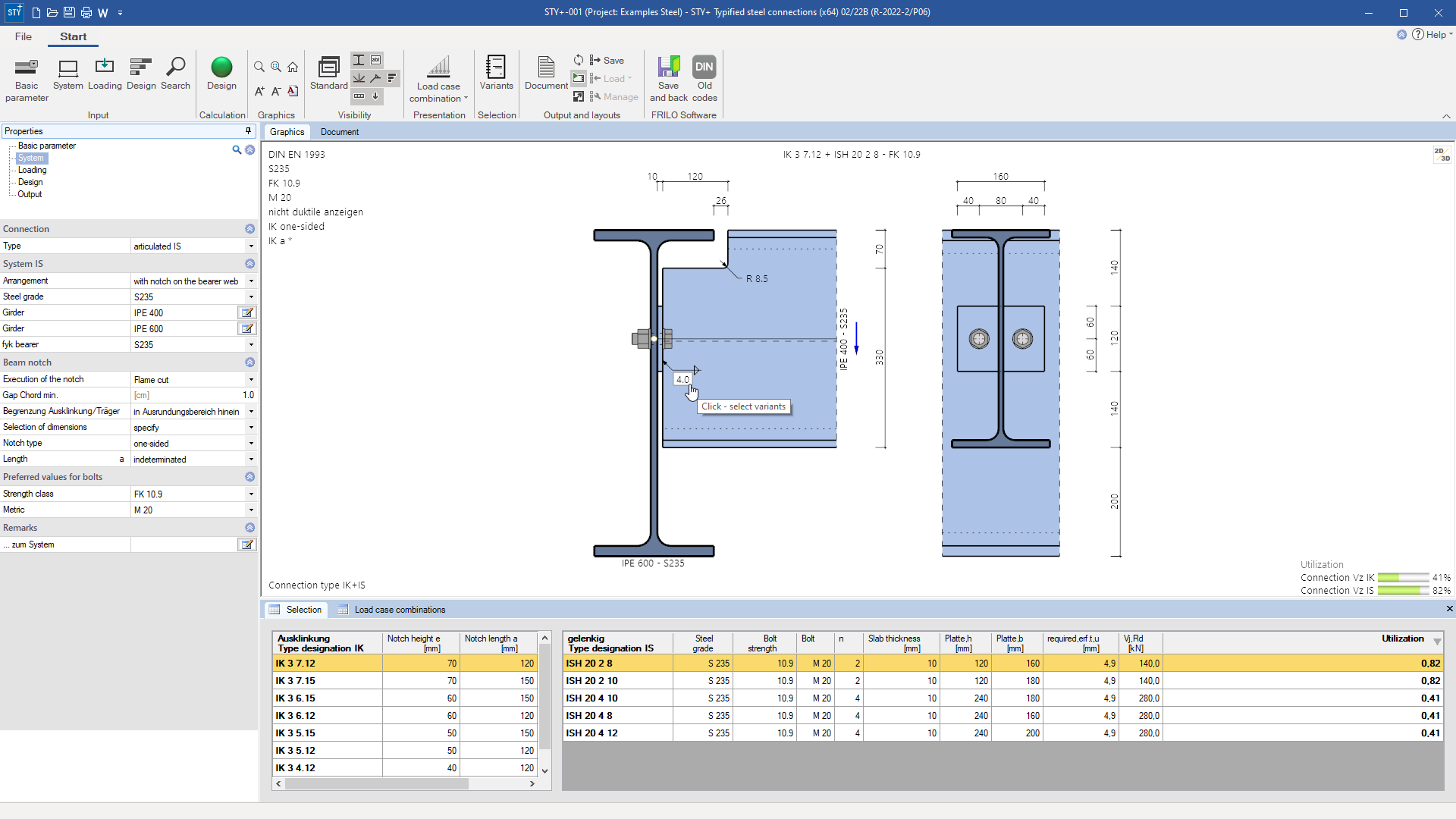

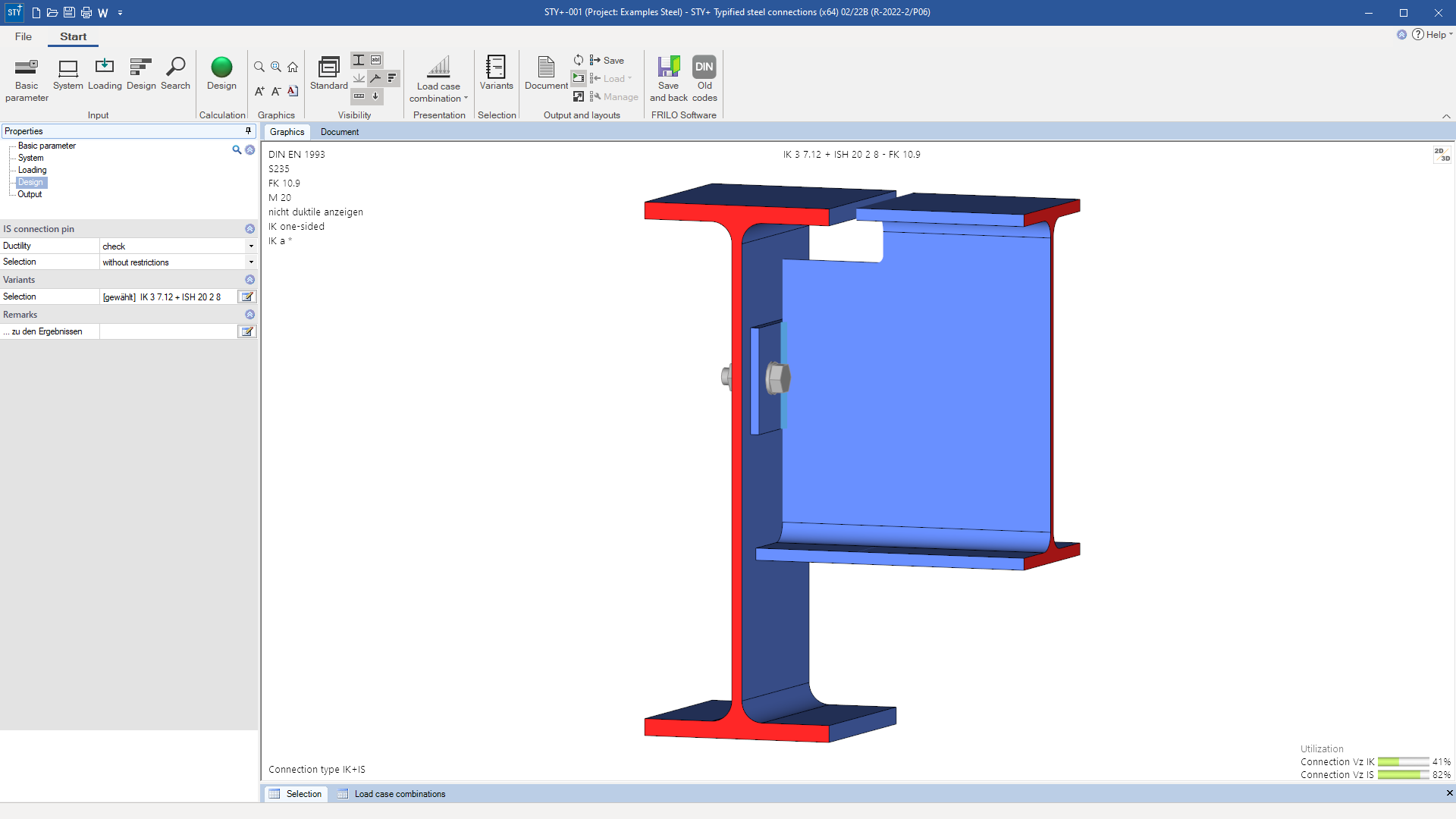

With the feature, fin plate connections in steel construction can be analyzed and designed. The program performs all required verifications for fin plate connections in the configurations “secondary beam to steel beam” or “secondary beam to steel column”.

Material

The material can be selected differently for the main beam, secondary beam, support and fin plate.

- Structural steel: S235, S275, S355, S450

- Annealed steel (S275N to S460N)

- Thermo-steel (S275M to S460M)

- Weathering steel (S235W to S355W)

- High-temperature steel (S460Q to S460QL1)

- Hollow section, hot-finished (S235H to S355H)

- Hollow section, hot-finished, fine-grain (S275NH to S460NH)

- User-defined steel

Structural system

Available systems:

- Fin plate connection: secondary beam to steel beam

- Fin plate connection: secondary beam to steel column

- Flexurally rigid connection at weld seam or at bolt centre of gravity

- For a connection to a beam, the secondary beam can have a notch on top, on bottom, or on both sides

Cross-sections:

- I-sections as standard shapes

- User-defined I-sections

Loads

- Depending on the selected design model (flexurally rigid at the weld seam or in the bolt pattern), design internal forces caused by axial force, moment, and shear force can be defined.

- Design internal forces refer to the centre of gravity of the bolt pattern.

- Multiple combinations of design internal forces can be entered.

Fasteners

- Bolts (black bolts and fit bolts)

- Sizes: M12; M16; M20; M22; M24; M27; M30; M36

- Strength classes: 4.6; 5.6; 8.8; 10.9

Design

Either the elastic or plastic cross-sectional resistance of the fin plate is verified. For the verification of the weld seam, the user can select whether the simplified or directional method should be used. For the bolted connection, the verification of the embedding pressure as well as the verification of shear action are performed.

Results

- Pre-defined standard scope

- Brief scope

- Extensive scope

File formats

- Word

- Printer

Import options

- ASCII

Export options

- Word

- ASCII

Steel construction

- DIN EN 1993

- ÖNORM EN 1993

- BS EN 1993

Support resources

News

Corporate headquarters as reinforced concrete skeleton structure

With the construction of a new corporate headquarters, Heidelberg Materials has demonstrated the remarkable range of reinforced concrete as an attractive building material. FRILO and Allplan were used by the structural engineers.

FRILO launches version 2024-2 with powerful updates for structural analysis and design

Highlights include the optimised design of Schöck Isokörbe®, the advanced integration of DC foundation engineering programs into the FRILO environment and new RSX interfaces for detail verifications in steel construction.