Casa Legno paves the way for solid timber apartment buildings

In the Swabian town of Metzingen, a sustainable and ecological lighthouse project in residential construction has been developed: With Casa Legno, one of the first apartment buildings in Germany was built in solid timber. The successful realisation of the construction project mainly relied on the patented technology of holzius GmbH from South Tyrol and the responsible structural engineers from the engineering office IBS Bau-Statik PartG, who provide insights into the constructive and structural challenges of their project work.

Constructing houses and buildings from wood raises numerous architectural and structural challenges for designers: the anisotropy of the wood, the stringent fire safety regulations and the protection against moisture. The construction of high-rise timber buildings in particular is dominated by discussions about real sustainability and safety. Nevertheless, wood increasingly represents a serious ecological and economic alternative in the construction of multi-storey buildings. The construction of timber buildings has since long ceased to focus only on family houses. As the professional organisation Holzbau Deutschland broke down in its 2022 status report, the share of approved new buildings in timber construction in both the residential and non-residential sectors amounted to approximately 21 % across Germany, which is an increase of 4 % since 2017 (Source: Lagebericht 2022 Holzbau Deutschland).

The benefits of timber as a building material

But why do builders, architects and engineers increasingly rely on wood as a building material, even in the construction of high-rise buildings and apartment blocks? The benefits of wood in terms of climate protection are obvious: Wood is a natural, renewable raw material that binds carbon dioxide. The use of wood in construction can demonstrably reduce the carbon footprint. In addition to the good results of the life cycle assessment, the pleasant indoor climate, the dry and quick assembly of timber elements and the high structural-physical quality favour the use of wood in the construction of high-rise and multi-family buildings.

The specifications of Casa Legno

One of these timber apartment buildings was erected as a lighthouse project in Metzingen in 2023. The Casa Legno (Italian for timber house) is assigned to building class 4 and comprises 16 condominiums and an underground car park. Only the underground car park and the building core required for bracing (staircase with lift) were constructed in reinforced concrete. The walls of the underground car park, the staircase and the lift were designed with a thickness of 24 cm. All exterior, interior and partition walls as well as the floors of the building were built in solid timber construction using the patented process by holzius GmbH from South Tyrol. The walls of the storey levels L0 to L3 were manufactured as holzius 180 mm solid timber walls following the DiBt approval ETA-15-0729. The slabs above L0 to L2 were designed as line-supported single-span beams using holzius 160 mm/180 mm/220 mm solid timber ceilings. The thickness depends on the span width and the load. The roof slab above L3 (partly with a cantilever) was designed as holzius 120 mm solid timber ceiling following the approval ETA-17-0745.

The functional principles of “dovetail” and “finger” jointing

The solid timber elements from holzius are based on the functional principles of dovetail and finger joints. They provide a solid timber system consisting of wall, roof and ceiling elements that benefit from the swelling and shrinking properties of wood and do not require any glue or metal joints. As a multi-layered upright block, the solid timber elements consist of vertically arranged and finger-jointed solid timber planks, which are connected with dovetail-shaped solid timber battens and thus achieve a high load-bearing capacity. Multi-storey buildings can therefore be realised without any settlement issues. Thanks to the precisely dimensioned clearance between the individual timber planks, no dimensional changes occur with moisture. By finger-jointing the ceiling elements, the entire ceiling surface is also trickle-proof.

IBS Bau-Statik is responsible for the structural design

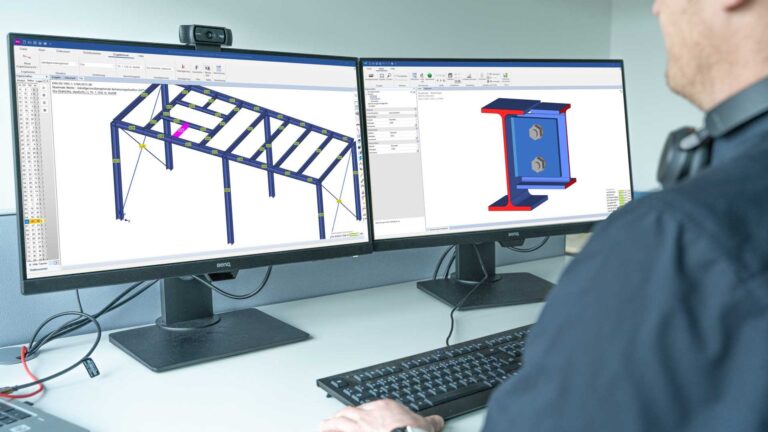

For the construction of Casa Legno and the special properties of the solid timber system by holzius, structural engineers were needed that had the necessary expertise and capacity for the structural calculation of this unconventional building. However, the builder, Sigrid Held GmbH from Grafenberg, had difficulties in finding a suitable office. “Originally, we were only commissioned to undertake the approval and implementation planning for the solid construction,” recalls Dipl.-Ing. Andreas Schnizler from the engineering office IBS Bau-Statik PartG. “Finally, we agreed to also provide the structural calculations and implementation planning for the timber construction in close cooperation with holzius. We were given enough time to acquire the necessary knowledge about the constructive details. In addition, holzius and an experienced structural engineer from Augsburg were on hand to advise us in regular video conferences,” Schnizler continues. In cooperation with his business partner Sebastian von Seggern (Bachelor of Engineering), he took over the entire structural design for the exciting building project, which was completed after only one year of construction. “The project has taken on a high priority in our office over the past year and a half,” von Seggern sums up because the two engineers had to overcome some constructive difficulties.

"FRILO's Building Model is aligned to solid construction processes. We succeeded in transferring the systematics on which the GEO Building Model is based to timber construction. But we were really challenged by the need to determine the correct masses."

Dipl.-Ing. Andreas Schnizler

The vertical load transfer with GEO

The major design challenge was to ensure that the horizontal and vertical loads would be safely transferred. The structural engineers assumed the vertical line loads to be transferred by the load-bearing exterior, interior and flat partition walls made of timber. Point loads could be borne by appropriate “reinforcement” of the solid timber walls. In exceptional cases, the loads were transferred via wooden posts or steel columns. A uniform footing was ensured by strip and concentrated foundations. For the determination of the vertical load transfer, the program GEO Building Model from FRILO was used. “FRILO’s Building Model is aligned to solid construction processes. We succeeded in transferring the systematics on which the GEO Building Model is based to timber construction. But we were really challenged by the need to determine the correct masses,” says Schnizler, referring primarily to the horizontal load transfer resulting from the seismic load case.

The horizontal bracing of the ceiling diaphragms

The eccentric position of the bracing solid access core and the associated eccentricity between the centre of mass and the shear centre resulted in a complex, irregular shear force progression. Using crossed fully threaded screws to close the corresponding joints of the individual solid timber elements would have been very time-consuming and uneconomical. Therefore, the solid timber ceiling elements were provided with a corresponding superstructure of derived timber boards, so that relatively stiff ceiling diaphragms were created.

Because the timber ceilings are composed of individual timber beams, the engineers used FRILO’s Continuous Beam program for the design. Vibration and fire safety analyses were also performed with the DLT+ program. For the design of the solid slab above the underground car park (h = 25 cm), the loads of the timber construction were applied and FRILO’s Slabs by Finite Elements program was used for the calculation. For the design of the foundations, the structural engineers relied on the FRILO programs FDS+ and FD+. “FRILO’s software is very user-friendly, straightforward and easy to use. It is ideally suited for everyday projects, such as single-family houses and multi-storey residential buildings, and its excellent price-performance ratio makes it stand out from other software providers,” Schnizler praises.

The horizontal bracing of the wall diaphragms

To determine the horizontal load distribution, the engineers determined the spring stiffnesses due to the shear stiffness of the walls (made of reinforced concrete and solid timber) and the resilience of the connecting joints of the timber ceilings to the reinforced concrete core (steel angles with timber screws). Due to the stiffness relations, a horizontal load distribution of 86 % on the reinforced concrete walls in the core and 14 % on the holzius solid timber walls resulted. The bracing and the transfer of the horizontal loads were therefore mainly accomplished by the massive staircase and lift walls. “As a rule, we had to base the calculation on the stiffnesses of the connecting joints because they were decisive and not the reinforced concrete core and its stiffness. In this case, sometimes only limit value considerations can be performed,” Schnizler points out just one of many challenges.

On the safe side, the decisive internal forces for the reinforced concrete walls were determined with 100 % horizontal load. Due to the eccentric position of the stiffening solid access core and the resulting torsional stress due to the horizontal load action in the longitudinal direction, the structural engineers only used individual solid timber walls, positioned as far out as possible in the ground plan, for the stiffening calculations and also calculated these on the safe side with 20 % of the horizontal loading. This horizontal load share of approx. 20 % on the solid timber walls was simulated with the help of the modified modulus of elasticity (1,400 N/mm²). “The comparison was important to be able to identify subsequently which walls become decisive in the different load cases,” explains the structural engineer von Seggern.

Seismic and fire safety analyses

Since the building is located in the seismic zone 2 on the Map of Seismic Hazards for Baden-Württemberg, analytical seismic verifications were also required. The seismic analysis for the load transfer via the reinforced concrete core was performed with a seismic behaviour factor q = 1.5. In a subsequent calculation, the verification for the solid timber walls was performed using a behaviour factor q = 2.5 (following the certificate from holzius and the approval Z-9.1-790) to determine more realistic seismic loads. In the FRILO Building Model, the resonating masses had to be entered in a modified form for the seismic analysis. Therefore, the engineers defined a slab thickness of 4 cm for the slabs above L0 to L2 and 3 cm above L3.

Because the FRILO Building Model provides the results for the wind and seismic loads with characteristic values, the input values were not increased γ-fold. However, to be able to compare the decisive internal forces from wind (γ=1.5) and seismic action (γ=1.0) in the result, the engineers applied the force coefficient 2.8 (resulting also from the coefficients ɣm and kmod) when defining the wind loads. For the fire safety verification, all load-bearing reinforced concrete components were designed to be fire-resistant R90 as per DIN EN 1992-1-2 and DIN 4102-4 without additional plaster finishing. The load-bearing timber components were designed following DIN EN 1992-1-2 and DIN 4102-4 with a fire rating of R60 (highly fire-retardant) for L0 to L2 and of R30 (fire retardant) for L3.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren