Stability Analysis for Steel

STX+

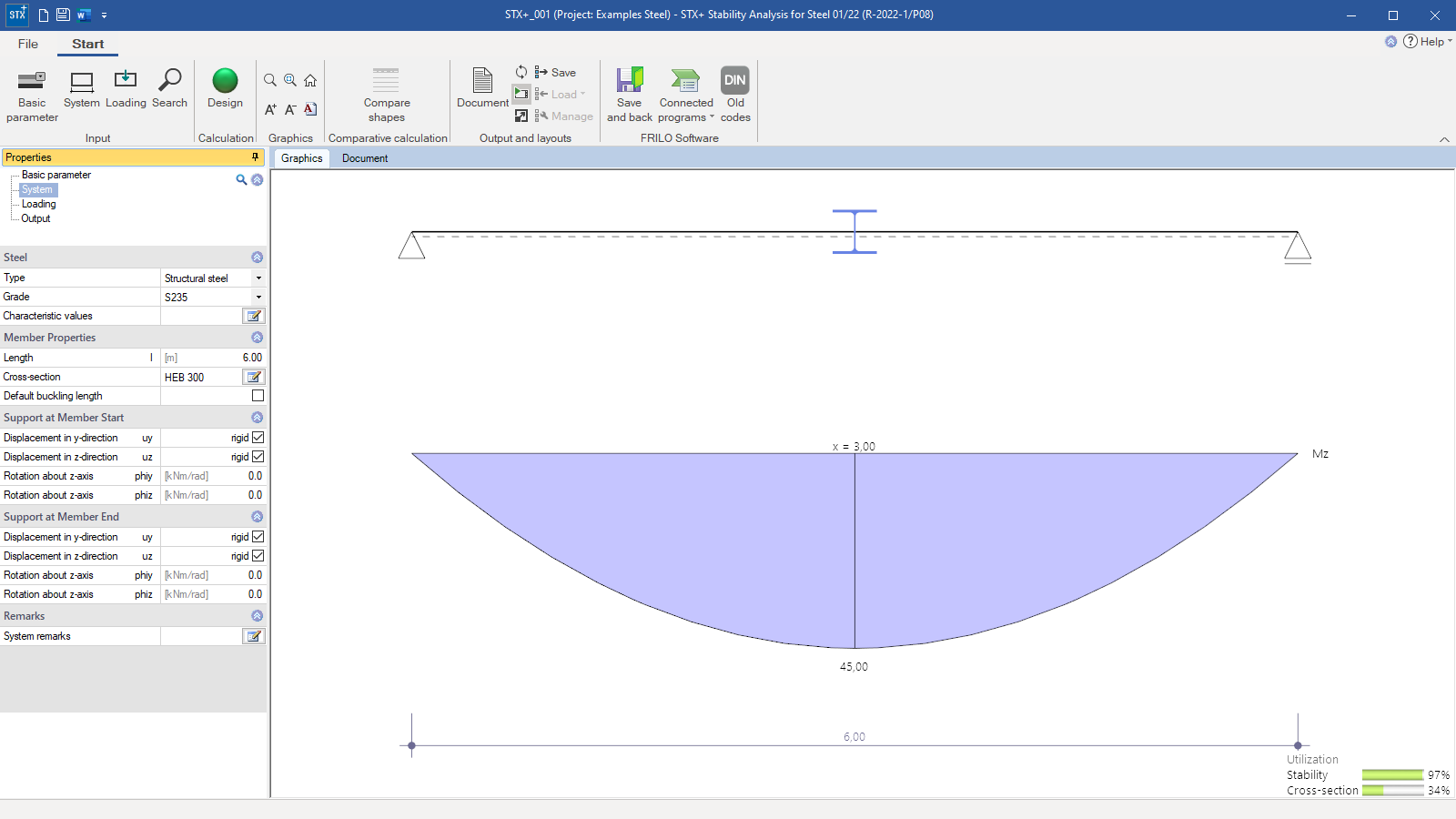

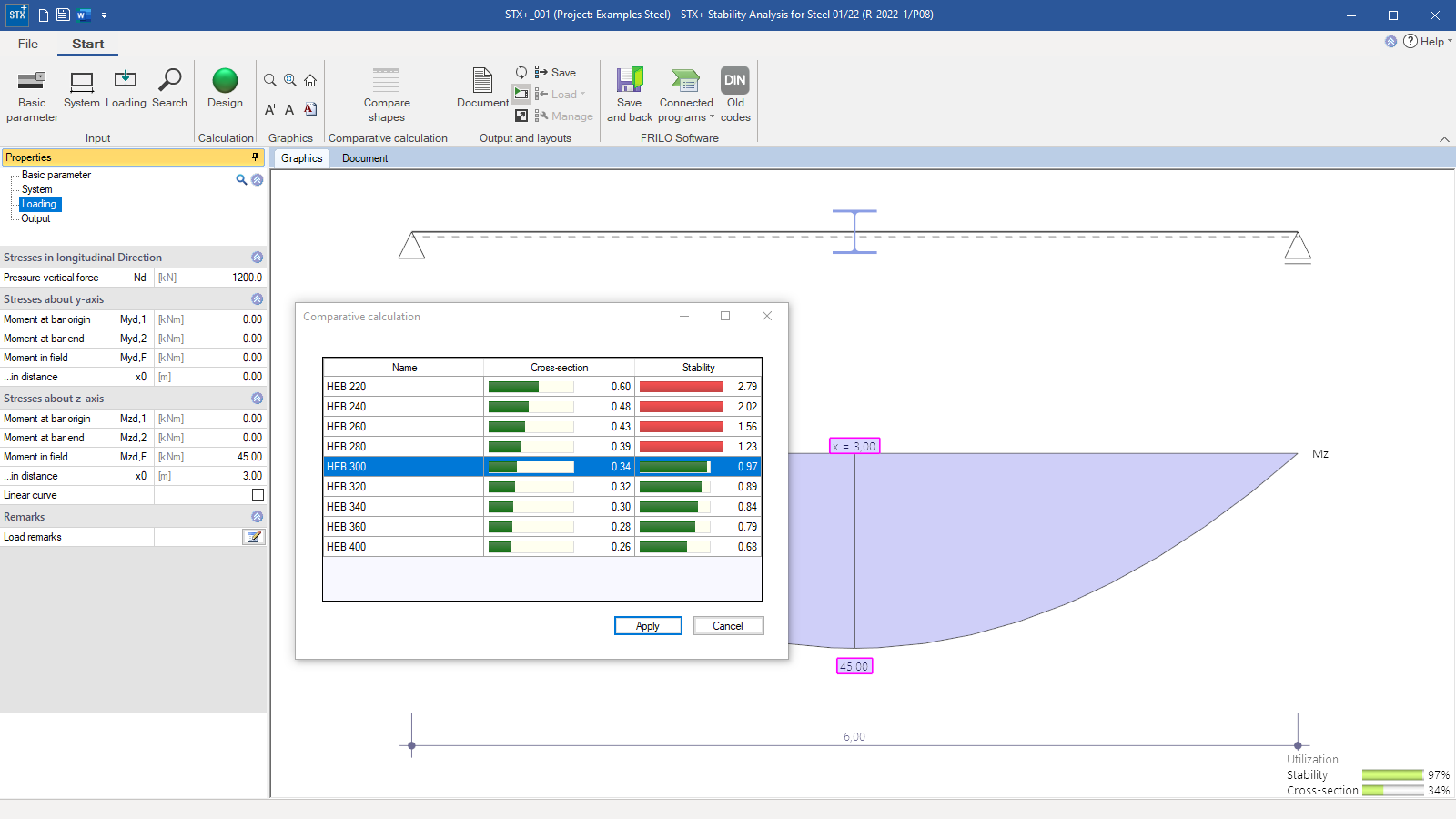

The STX+ program is used to perform stability verifications for single-part members with fork supports based on the equivalent member method.

Discover now more programs from the section Steel!

SHOW MOREMaterial

- Structural steel: S235, S275, S355, S450

- Annealed steel (S275N – S460N)

- Thermo-steel (S275M – S460M)

- Weathering steel (S235W – S355W)

- High-temperature steel (S460Q – S460QL1)

- Hollow section, hot-finished (S235H – S355H)

- Hollow section, hot-finished, fine-grain (S275NH – S460NH)

- User-defined steel

Structural system

Available systems:

- Statically determined, fork-mounted single-span beam.

Cross-sections:

- I-sections, I-sections with inclined flange, rectangular and circular hollow sections as standard shapes or user-defined sections.

Supports:

- Rigid or elastic supports at both ends.

- Rotational springs about the y-axis and about the x-axis can be defined at the member ends.

- The effective length can be pre-set.

Loads

- Definition of the actions via the design internal forces.

- Axial compressive force.

- Moments about the y-axis and about the x-axis at one or both ends of the member and in the span at any point x.

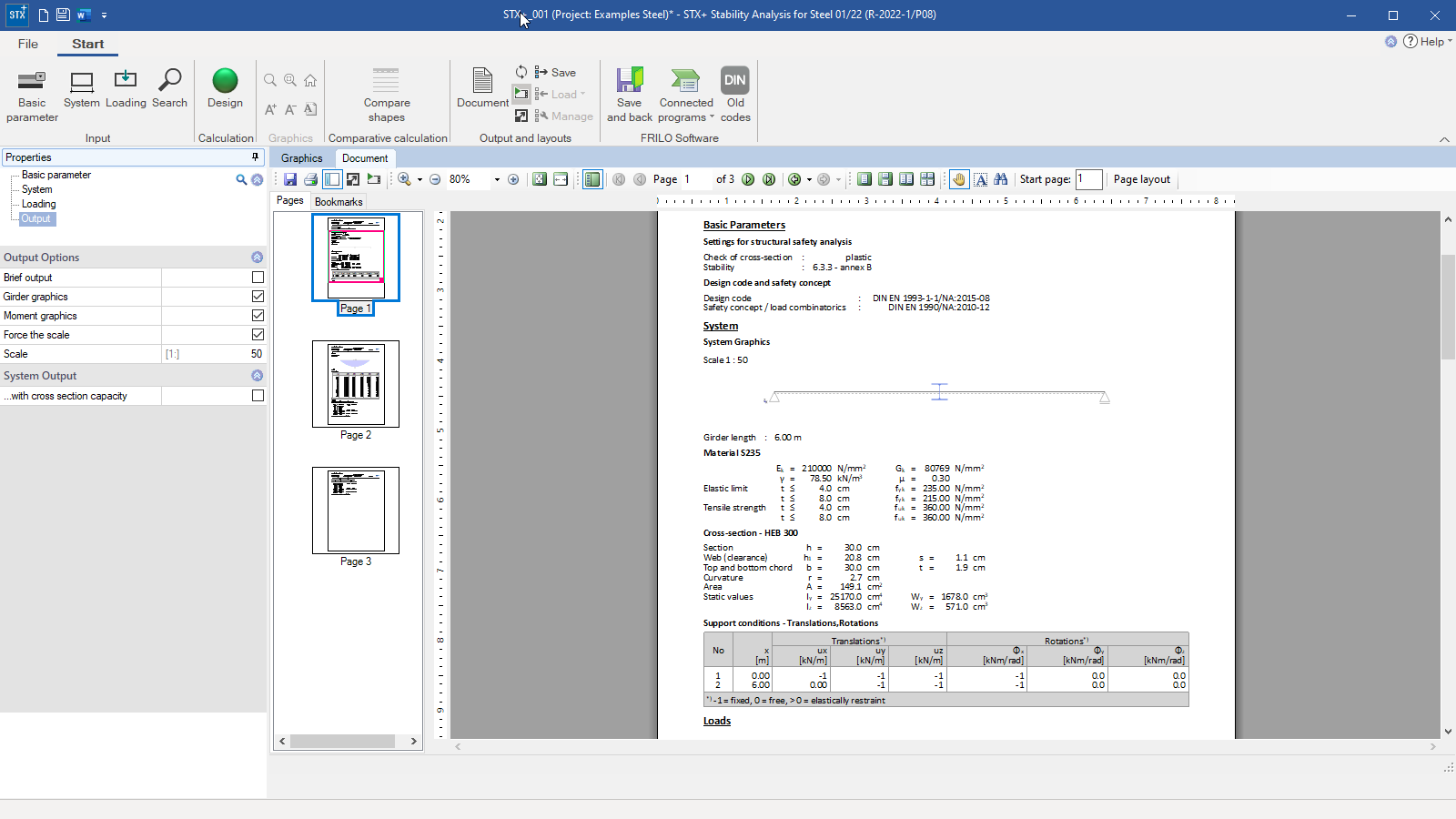

Structural safety

Either the elastic or plastic cross-sectional resistance is verified. Furthermore, the verification of the system’s load-bearing capacity is performed using the equivalent member method either in accordance with section 6.3.3 Annex A or B or with section 6.3.4.

Document file formats

- Word

- Printer

Output

- pre-set brief output

- user-defined scope

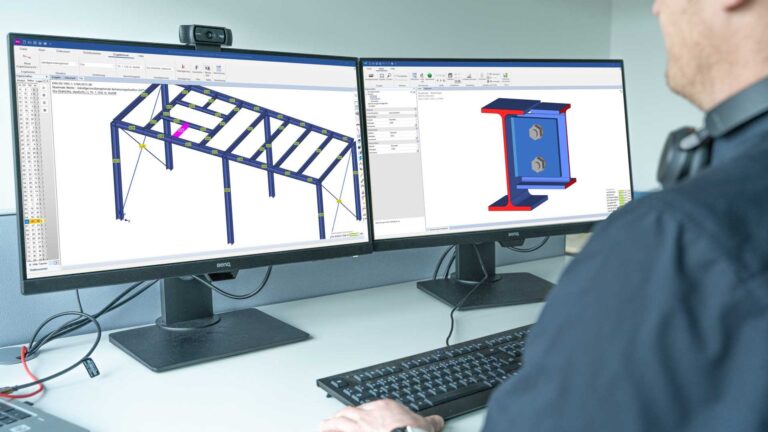

Transfer options

- Lateral Torsional Buckling Analysis BTII+

Import options

- FRILO XML

- ASCII-file

Export options

- Word

- ASCII-file

- FRILO XML

Steel construction

- EN 1993

- DIN EN 1993

- ÖNORM EN 1993

- BS EN 1993

News

FRILO launches version 2024-2 with powerful updates for structural analysis and design

Highlights include the optimised design of Schöck Isokörbe®, the advanced integration of DC foundation engineering programs into the FRILO environment and new RSX interfaces for detail verifications in steel construction.

Load determination for eight-floor perimeter block development with FRILO Building Model

Find out how the structural engineers at bauart Konstruktions GmbH determined the loads for an eight-floor perimeter block development in Frankfurt’s Europaviertel district using the GEO from FRILO.